Electical Inspections

Pipeline Inspection

CCTV Inspections

Structural Inspection

Underground Locating

Marine Inspection

Predictive Maintenance

Research & Development

Mechanical Inspections

Reduce unexpected downtime.

Reduce Repair cost.

Briton Infrared are specialists in predictive maintenance programs. Not just certified Infrared Thermographers, also qualified Heavy Plant and equipment technicians.

Our predictive maintenance programs can provide you with relevant practical information to assist you in reducing downtime and repair costs over a wide range of your mobile and fixed plant as well as electrical networks.

Predicate maintenance surveys are generally undertaken on a monthly basis for best results and to enable trending for predictive maintenance purposes, however 3 monthly, 6 monthly or annual surveys still deliver results that will ultimately save your operation money.

Surveys can be tailored to suit your requirements, we can inspect various areas of your operation:

Programs are easily integrated with existing maintenance programs.

Surveys are non evasive will little or no disturbance to daily operation.

Safety at distance - few other methods can inspect for faults at a safe distance from moving or rotation machinery and high voltage equipment.

Diversity - no other mass screening method can be used over such a wide range of equipment and components.

Contact us to discuss and predicate maintenance program for your facility.

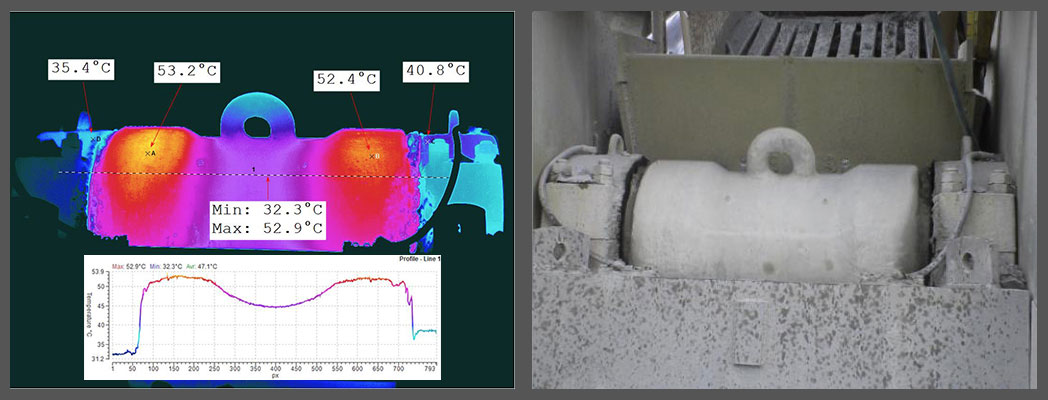

The above image is of a primary jaw crusher in a large quarry. Few other Infrared providers have the vast experience in heavy mechanical systems to be able to provide accurate monitoring and recommendations in large industrial operation such as this. Predictive maintenance programs provided by Briton Infrared help protect investments such as this.

The above image is of a primary jaw crusher in a large quarry. Few other Infrared providers have the vast experience in heavy mechanical systems to be able to provide accurate monitoring and recommendations in large industrial operation such as this. Predictive maintenance programs provided by Briton Infrared help protect investments such as this.

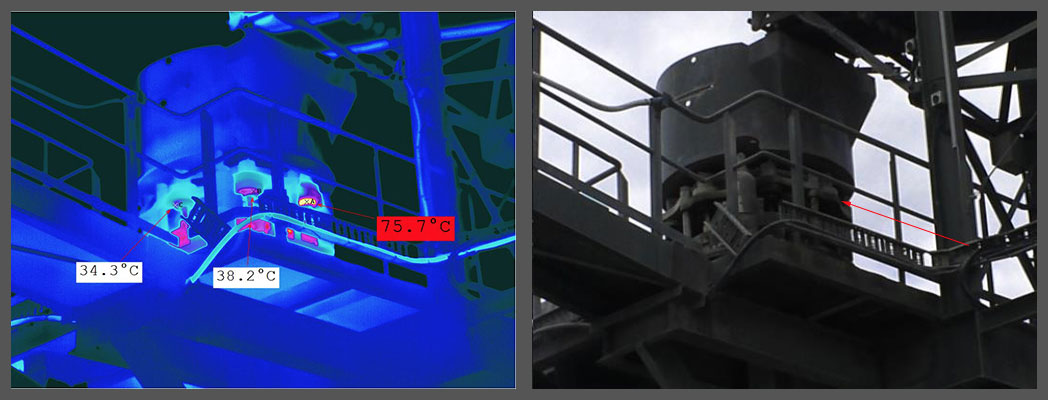

This cone crusher has a failing slider, fault was spotted during a monthly site survey. This fault is shot at over 25 meters well out of harms way. We are but a few IR surveyors around nation wide with the high end equipment and knowledge to deliver such results.

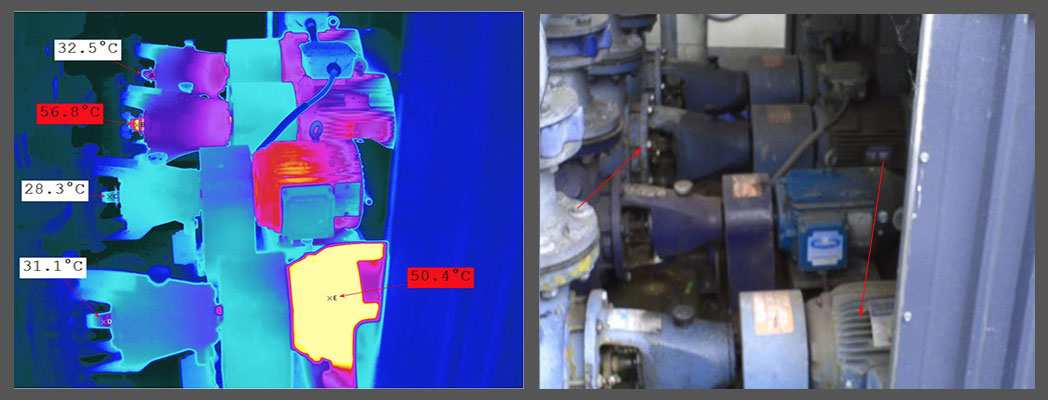

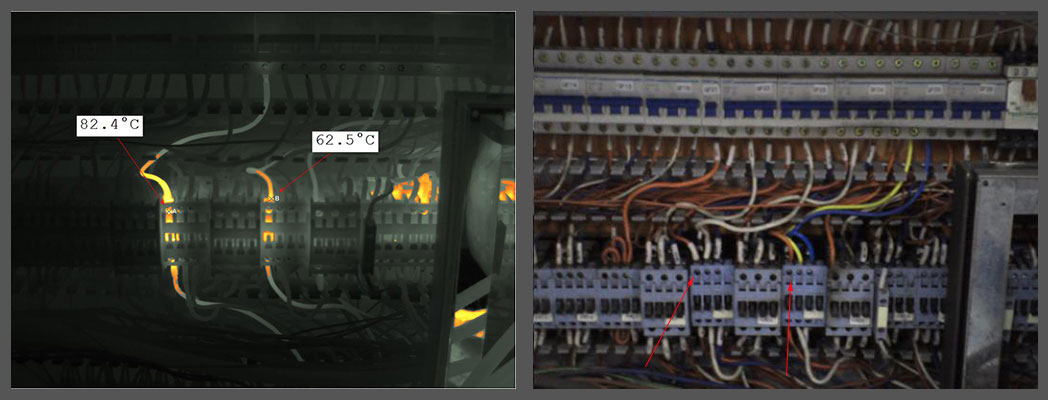

This cone crusher has a failing slider, fault was spotted during a monthly site survey. This fault is shot at over 25 meters well out of harms way. We are but a few IR surveyors around nation wide with the high end equipment and knowledge to deliver such results. Our predictive maintenance programs cover all aspects of your operation. These poor connections in a control cabinet are but a few of the faults we ID during our routine predictive maintenance surveys. Faults such as this may look minor can often bring down a major part of any operation, don't get caught out call us now!

Our predictive maintenance programs cover all aspects of your operation. These poor connections in a control cabinet are but a few of the faults we ID during our routine predictive maintenance surveys. Faults such as this may look minor can often bring down a major part of any operation, don't get caught out call us now!

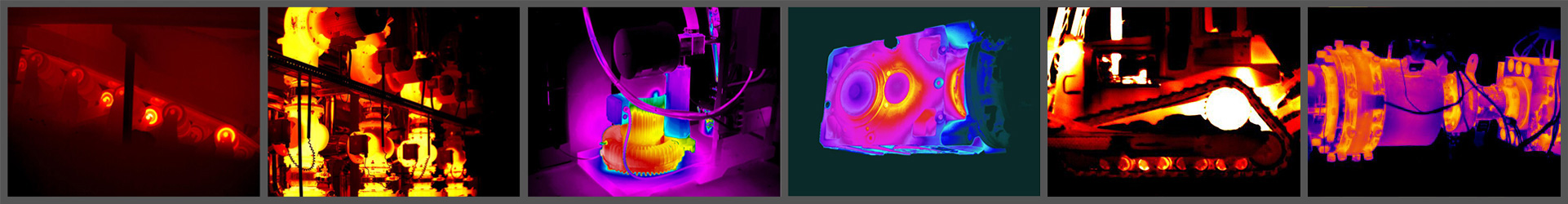

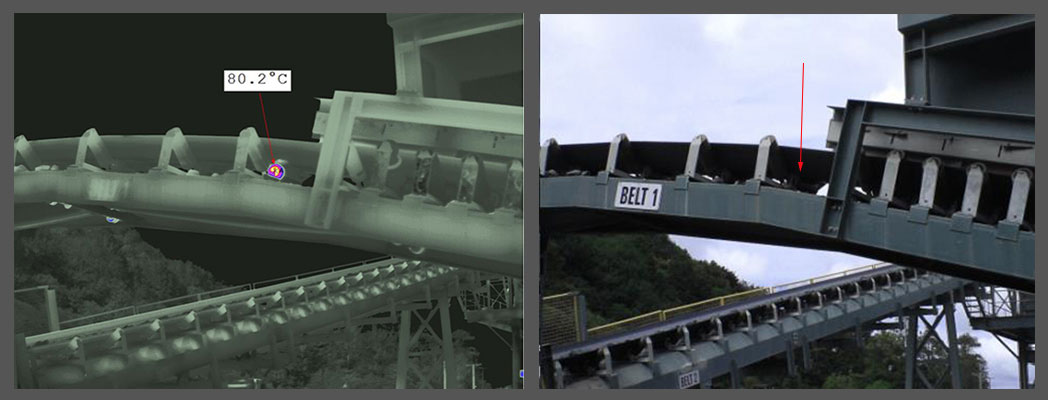

We often hear comments such as "just rollers, we don't really care" However everyone cares about their belts, especially when its torn to shreds by a collapsed roller. You will see in this image the effects of a seized roller and wear being inflicted on the belt. Yet another reason to implement a Briton Infrared predictive maintenance program.

We often hear comments such as "just rollers, we don't really care" However everyone cares about their belts, especially when its torn to shreds by a collapsed roller. You will see in this image the effects of a seized roller and wear being inflicted on the belt. Yet another reason to implement a Briton Infrared predictive maintenance program.