Electical Inspections

Pipeline Inspection

CCTV Inspections

Structural Inspection

Underground Locating

Marine Inspection

Predictive Maintenance

Research & Development

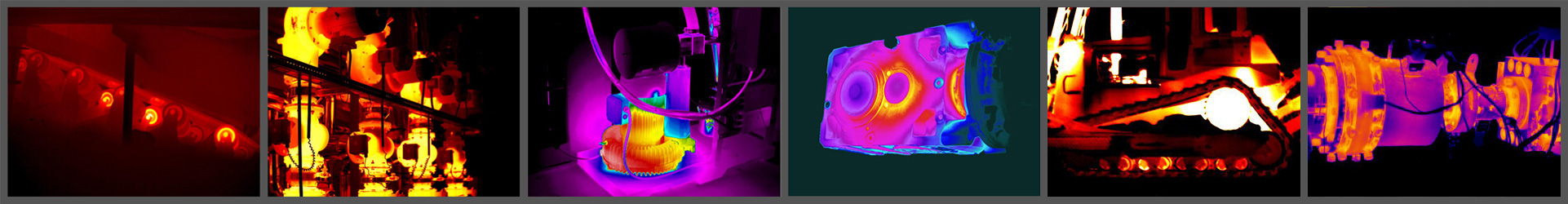

Mechanical Inspections

Briton Infrared are specialists in mechanical inspections and diagnostics.

Combining vast experience with industrial mechanical and hydraulic systems plus extensive infrared testing & development, has given us the ability to provide a range of specialized mechanical inspections and diagnostic solutions.

We are able to provide you with services such as:

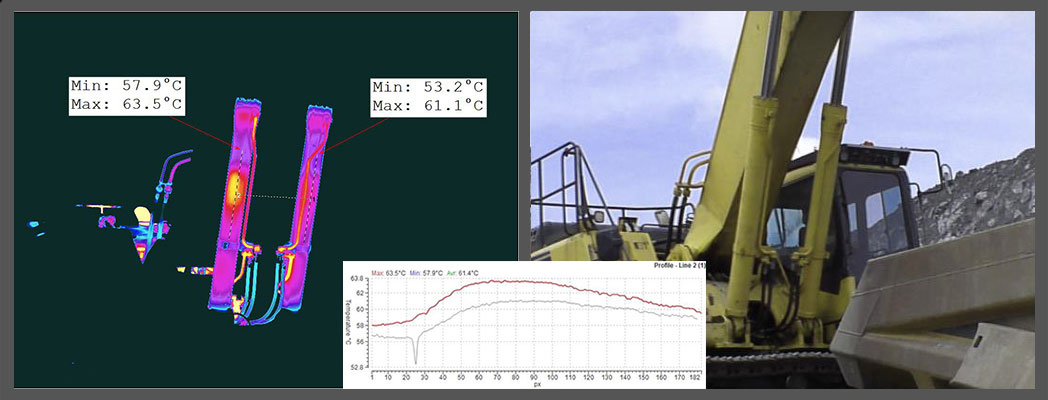

Both long range and close up accurate analysis of pin temperatures, a great way to check auto lubrication issues or just regular inspection on excavators, cranes and other heavy industrial machinery were access under operation is not possible.

Having a shutdown and want to know what bearings may need attention or concerned about over or under lubrication of bearings on your site. We can check and report accurate bearing temperatures in all sorts of locations, both long range and close up.

We are specialists in hydraulic system diagnostic assistance, Having a nightmare diagnosing a hydraulic system with conventional testing methods? we can help identify pump issues such as bypass and internal bearing problems, hydraulic cylinder issues such as minor bypass or side loading issues, cooling issues, valve bank bypass, hose blockages and restrictions.

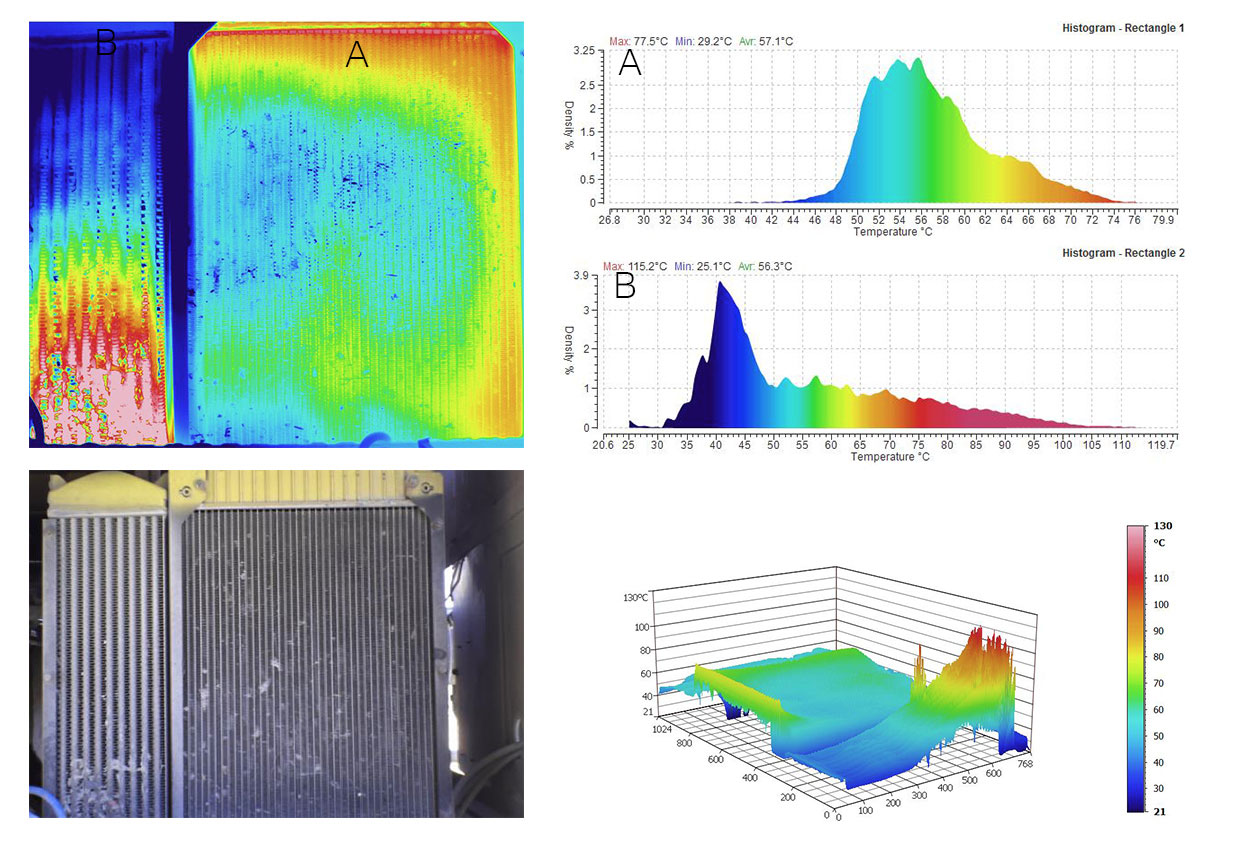

We identify internal and external blockages, air flow issues, map efficiency and can provide detailed reports and recommendations on your cooling systems performance. Or simply provide a quick affordable check to help you with overheating issues.

Oil coolers, heat exchangers and after-coolers are often difficult to check, with out high end equipment and analyzing software we can provide accurate detailed inspection and analysis of various coolers on a range of industrial and marine equipment.

Industrial water pumps can often go unchecked until the worst happens and it fails, Often over looked but critical to the operation of many industrial facility's everywhere. We can provide fast inspection for internal and external bearing issues, drive issues and in some cases we have even ID loose impellers rubbing on the housing. It is more often still a lot cheaper to rebuild a large pump rather than replace after complete destruction!

We can identify internal bearing issues, bypass and impeller or vain drag on housing. Once again a rebuild on a big unit is generally cheaper than replacement after catastrophic failure.

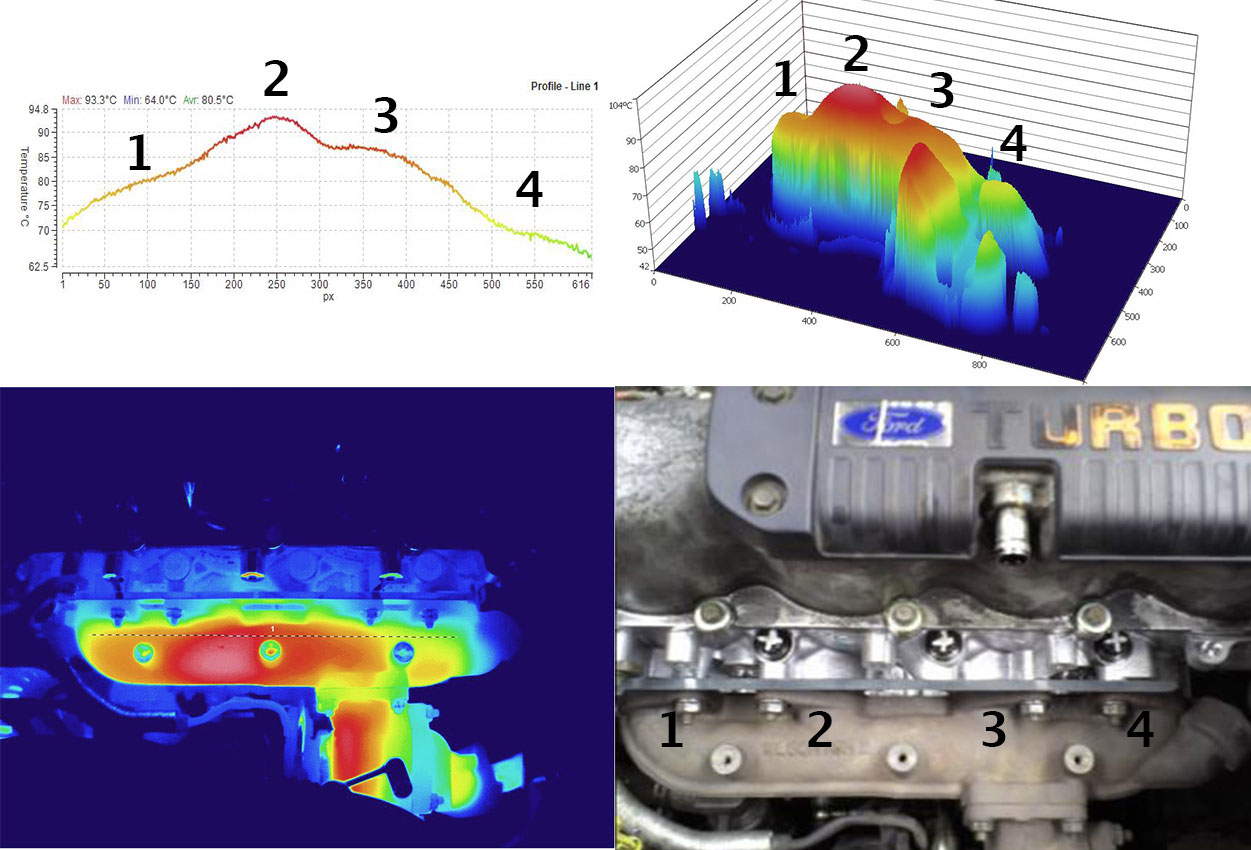

Thermal imbalance of cylinders - we can tell you accurate exhaust temperatures on each cylinder, head temperatures, missing insulation under exhaust lagging, Identify exhaust leak location under insulation. Id exposed exhaust areas over 220 degrees C that will ignite gas and flammable mist as instructed by SOLAS for marine engine rooms. Locate blockages in cylinder heads and engine blocks.

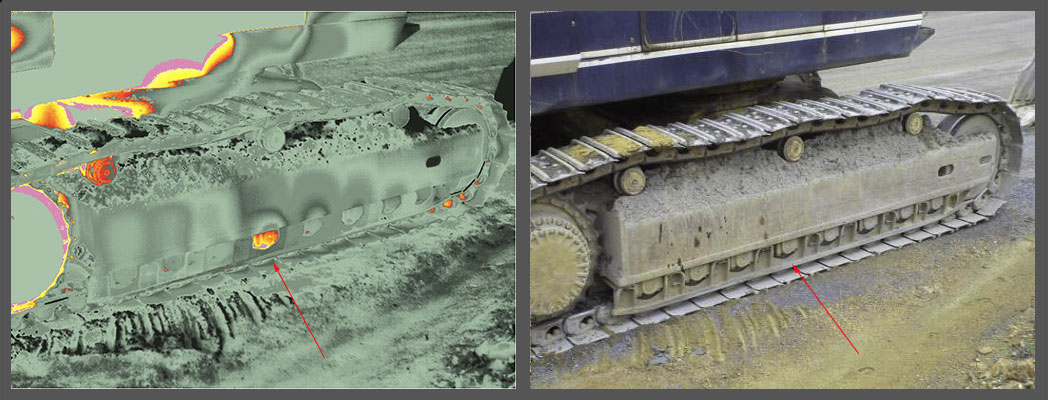

We can identify at long range out of harms way, wet change link lubrication issues, roller faults and overheated drive gear.

Briton Infrared's mechanical thermography service is a very fast, cost effective way to assist you in diagnosing and mass screening various mechanical components and systems in your operation.

Briton Infrared's mechanical thermography service is a very fast, cost effective way to assist you in diagnosing and mass screening various mechanical components and systems in your operation.

Conventional methods of testing and diagnosing hydraulic cylinders provide accurate results and in most cases are the best method of diagnosing cylinder problems. However with on going research and development and hundreds of cylinder inspections undertaken, Briton Infrared has developed very unique methods of testing and diagnosing cylinder problems. Sometimes time restraints, environmental restrictions and location can provide big challenges with cylinder testing. Our innovative methods and vast hydraulic experience and knowledge has given us the ability to provide this very specialized service. The above machine had symptoms of a minor boom creep, only under full load situations and only after many hours of work. Conventional testing was undertaken however results were inconclusive. We were able to ID this minor R/H boom cylinder bypass where other methods had failed, instantly.

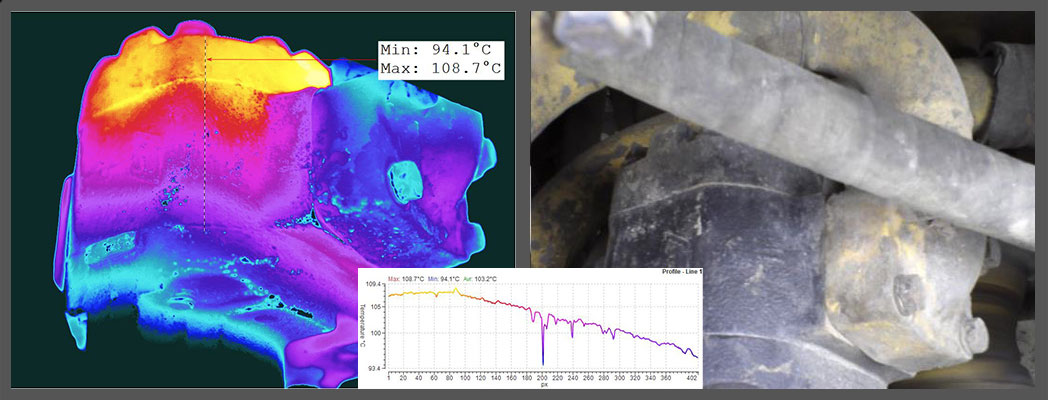

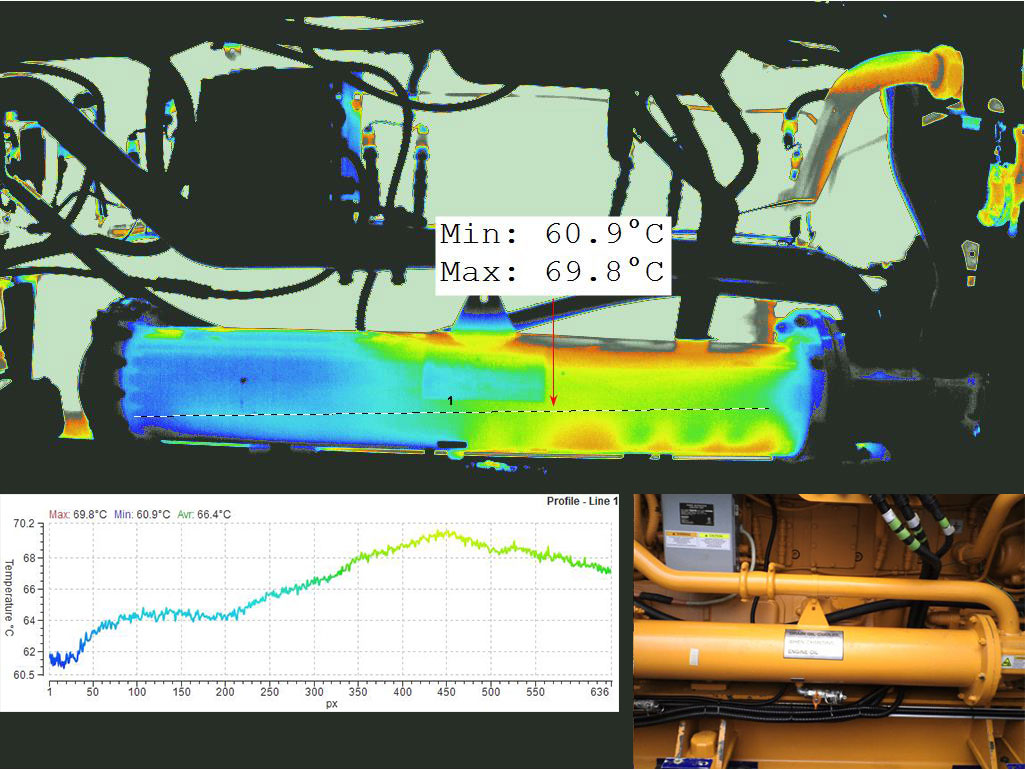

The above images are of a gyro stabilizer unit in a 22 meter launch, This vessel had a on going issue with a intermittent overheating fault in the forward stabilizer all standard checks and troubleshooting procedures had been undertaken with little conclusive results. After many attempts by the service agents and interdependent experts and no solid results, Briton infrared was contracted to investigate this issue, We inspected cooling system operation through a run up and run down process and checked and logged body temperatures and thermal patterns in the unit. Within a few hours of being on site we identified the fault to be a top bearing issue. You will see on the temperature profile graph the spike in the position where the outer bearing race sits in the body. Specialist investigations such as this are what makes our service so unique, few other IR providers have the mechanical knowledge, IR experience and equipment to deliver these results.

The above images are of a gyro stabilizer unit in a 22 meter launch, This vessel had a on going issue with a intermittent overheating fault in the forward stabilizer all standard checks and troubleshooting procedures had been undertaken with little conclusive results. After many attempts by the service agents and interdependent experts and no solid results, Briton infrared was contracted to investigate this issue, We inspected cooling system operation through a run up and run down process and checked and logged body temperatures and thermal patterns in the unit. Within a few hours of being on site we identified the fault to be a top bearing issue. You will see on the temperature profile graph the spike in the position where the outer bearing race sits in the body. Specialist investigations such as this are what makes our service so unique, few other IR providers have the mechanical knowledge, IR experience and equipment to deliver these results.

Tired of not being able to find that pesky squeaking roller... We can help. On larger machines overhauling rollers is still usually cheaper than replacing them. We can ID rollers in even the early stages of failure or oil loss, at long range and whilst in operation.

Tired of not being able to find that pesky squeaking roller... We can help. On larger machines overhauling rollers is still usually cheaper than replacing them. We can ID rollers in even the early stages of failure or oil loss, at long range and whilst in operation.

The above hydraulic pump has bypassing rear valve plate seals, once again it is our high end equipment and infrared experience, coupled with vast hydraulic system knowledge that enables us to pinpoint faults such as this. With hours of R&D into thermal patterns of both good and bad pumps has given us this unique capability.

The above hydraulic pump has bypassing rear valve plate seals, once again it is our high end equipment and infrared experience, coupled with vast hydraulic system knowledge that enables us to pinpoint faults such as this. With hours of R&D into thermal patterns of both good and bad pumps has given us this unique capability.

Radiator and Inter cooler inspection and analysis. We ID external and internal blockages. We also provide detailed efficiency reporting and analysis, giving you the ability to know your systems have plenty of reserve when the going gets tough, this service is especially useful when testing and developing custom power packs and drive packages in your operation.

Radiator and Inter cooler inspection and analysis. We ID external and internal blockages. We also provide detailed efficiency reporting and analysis, giving you the ability to know your systems have plenty of reserve when the going gets tough, this service is especially useful when testing and developing custom power packs and drive packages in your operation.

Briton infrared offers oil cooler, fuel cooler and and heat exchanger analysis and inspection. We ID internal blockages and map cooler performance or simply provide efficient cooling system diagnostic assistance.

Briton infrared offers oil cooler, fuel cooler and and heat exchanger analysis and inspection. We ID internal blockages and map cooler performance or simply provide efficient cooling system diagnostic assistance.

Briton infrared is equipped with real time 3D analysis systems. This service is very use full for mapping engine cylinder thermal imbalance. We offer active assistance with engine faults when compression/blow-by/cutout testing is perhaps not producing the desired results.

Briton infrared is equipped with real time 3D analysis systems. This service is very use full for mapping engine cylinder thermal imbalance. We offer active assistance with engine faults when compression/blow-by/cutout testing is perhaps not producing the desired results.